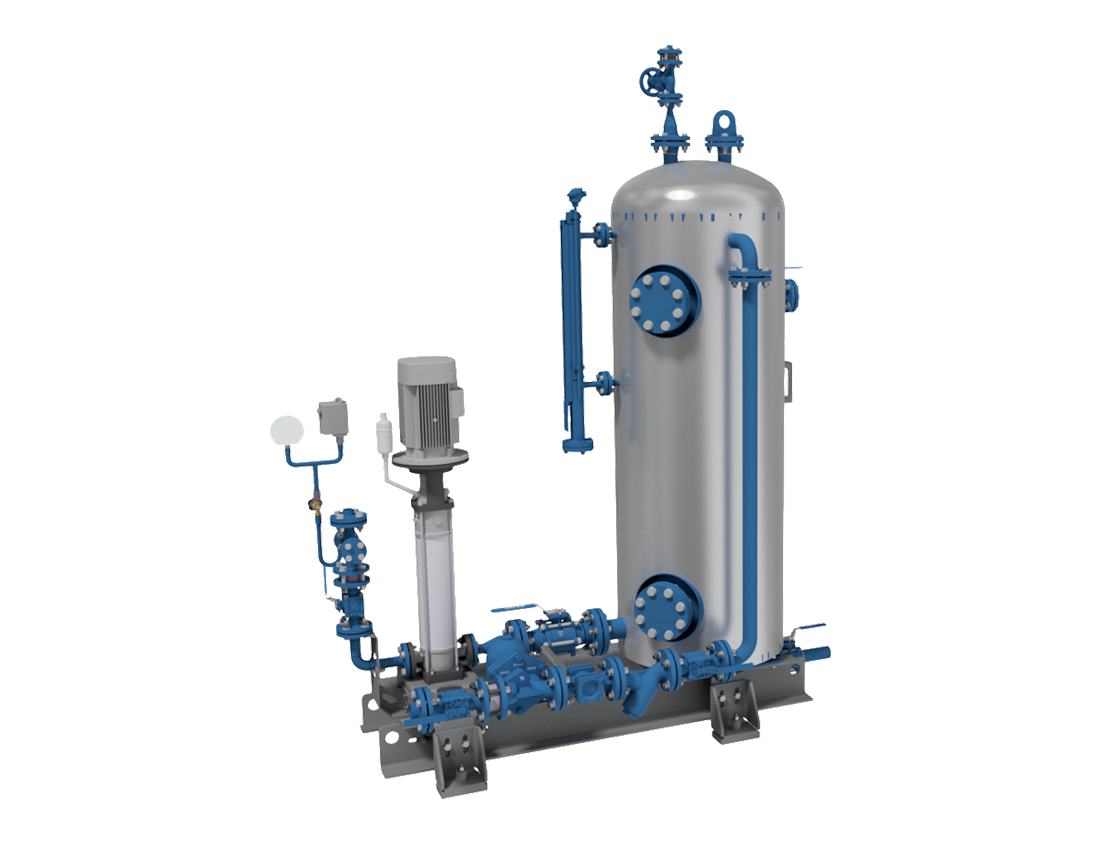

Steam Condensate Return System

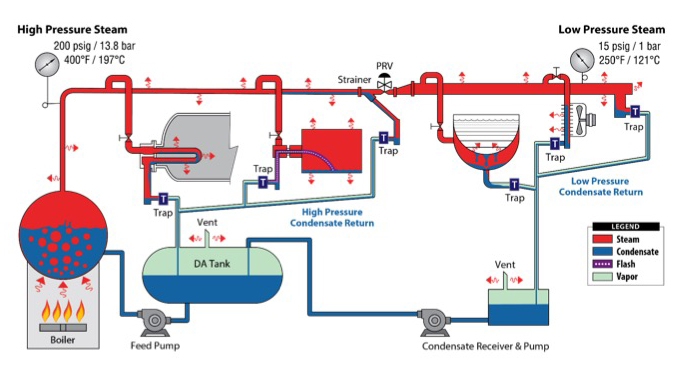

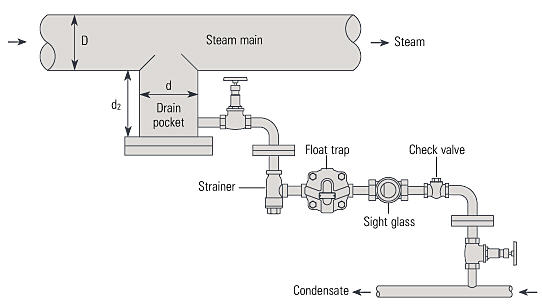

Steam condensate return system. Steam branch lines take steam from steam main to steam-heated unit. Standard Condensate Return Stations Roth Standard Steam Condensate Return Stations are the most popular and meet most water applications. Condensate can contain up to 20 of the energy required to make the steam in the boiler.

System backpressure can be calculated by totaling the sum of 3 discharge side components. If it is contaminated it will probably be sent to drain. Roth steam condensate pump return stations eliminate boiler system problems and continue to provide the efficient return of hot condensate to the boiler or feedwater system.

Condensing equipment in the steam system usually includes copper or copper alloys because of its favorable heat transfer characteristics. These units will deliver hot water at temperatures up to 200 F 93 C and will not vapor bind at 210 F 98 C. The most efficient system is a condensate return system controlled at a pressure as close to the boiler operating pressure as possible.

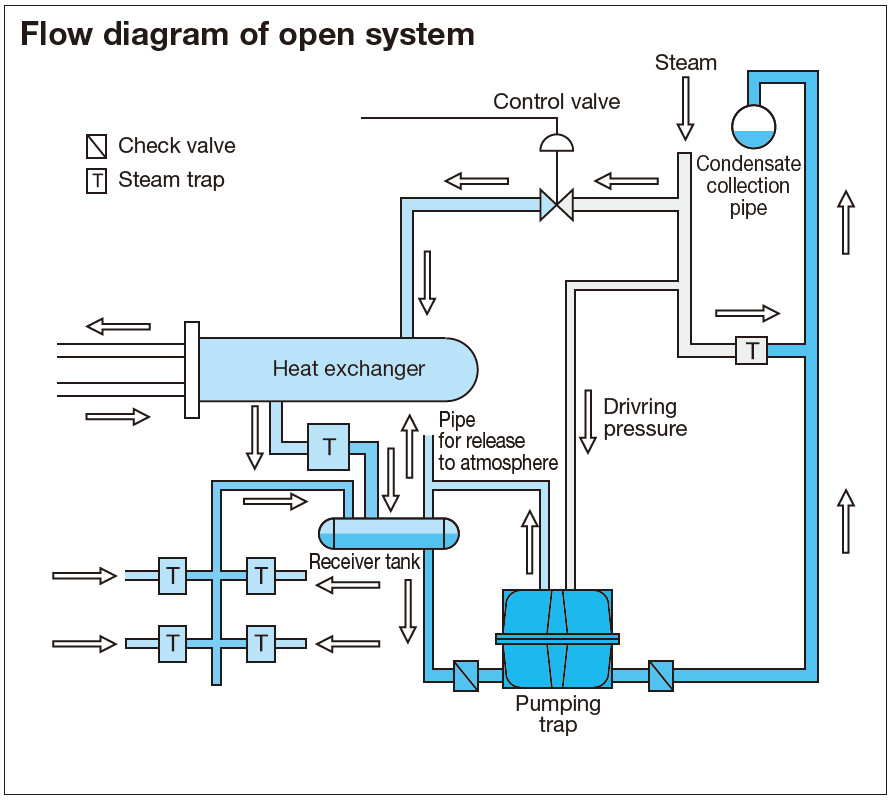

If not the valuable heat energy it contains can be retained by returning it to the boiler feedtank. The condensate enters the condensate drainage system. In a vented condensate recovery system steam trap inlet pressure or a condensate pump is used to return condensate to an open-to-atmosphere collection tank for use as boiler make-up water pre-heat or other hot water applications.

This is possible if the plant doesnt use direct steam injection for process applications. Flash steam is discussed briefly in Module 141 and in more detail in Module 22. Condensate return systems are certainly not high technology but keep in mind that a steam system may be the lifeblood of not just one but many operations throughout a plant.

Steam Condensate Return System - posted in Industrial Professionals. In a heating process condensate is the result of steam transferring a portion of its heat energy known as latent heat to the product line or equipment being heated. The condensate is collected in the condensate collection drum through a Spirax Thermo float ball steam trap.

However the limitation is the type of steam and condensate system. The most efficient system will be a condensate return system that is controlled at a pressure as close to the boiler operating pressure as possible.

Depending on the pressure condensate leaving a trap contains approximately 20 of the heat energy transferred at the boiler in the form of sensible heat.

This is possible if the plant doesnt use direct steam injection for process applications. Standard Condensate Return Stations Roth Standard Steam Condensate Return Stations are the most popular and meet most water applications. Selecting a Condensate Return System The steam tracing system typically modulates the steam pressure to the steam tracer system. Condensate can contain up to 20 of the energy required to make the steam in the boiler. Often the condensate which forms will drain easily out of the plant through a steam trap. Condensate recovery allows you to use all of the valuable Btu within the steam system. In a perfect system. Condensate return lines are constructed primarily of mild steel and can be extensive in total length throughout the plant. The steam to the heaters is controlled by the naphtha outlet temperature.

Avoiding downtime in the steam system of which the condensate return pump is an integral part ranks highly on the list of Important Things for Plant Operations. Condensate can contain up to 20 of the energy required to make the steam in the boiler. This is possible if the plant doesnt use direct steam injection for process applications. If it is contaminated it will probably be sent to drain. In a heating process condensate is the result of steam transferring a portion of its heat energy known as latent heat to the product line or equipment being heated. Condensate water or condensed steam reduces the quality of the steam but is too high value to discard. Receiver capacities to 50 gallons 189 liters can be supplied on these units.

Post a Comment for "Steam Condensate Return System"